Valves For Special Application

Low emission Service Valves

Low Emission Valves are utilized when emission of the working fluid in the external atmosphere is undesirable due to environmental, safety or economic reasons. In such cases the stem seals need to have paid particular attention and specially-engineered arrangements are frequently employed. For smaller sizes (up to 6” size) a bellow seal may be used to prevent leakages of the fluid and a secondary stem seal in the form of a packed gland or o-ring is often supplied in case of bellows failure. Bellow seals are often used in rising stem design (gate, globe) but are also available for quarter turn valves (ball, butterfly, etc.).

Cryogenic Service Valves

Valves for cryogenic applications (below -50°C) should comply with BS 6364. They are normally equipped with extended bonnets, which allows a reasonable temperature gradient up to the gland and to the point of operation. It also allows a liquefied gas to reach a vaporizing temperature. Normal leakages are not accepted for cryogenic service because leaking fluid could freeze and affect the operation of the valve. Seats and seals are often made in KEL-F and soft seated valves require devices for relieving the overpressure caused by thermal expansions due to temperature rise.

High Temperature Valves

Gate, Globe and Check valves shall be selected on the body and trim materials taking into consideration the pressure class.

Materials of Ball valves shall be selected with more accuracy in order to grant the sealing.

Ball valves are often equipped with extended stem to dissipate the high temperature.

According to the temperature degree (from 200°C to 1.000°C) body and sealing will be proposed in accordance with the process conditions.

Deluge Valves

Soft Seated valves, including high performance butterfly valves and extremely high vacuum, shall be specified and a metal-to-metal closing mechanism is likely to be provided. Bellow stem seals may be specified and secondary packing may be required.

Valve packing must be suitable for 25 mm Hg absolute pressure.

Excess Flow Valves

Excess flow rate are designed to close automatically when the flow through them exceeds a specific rate. They must be installed where the fluid leakage through a damaged line would cause serious damage and must be located as close as possible to the equipment to be protected.

Emergency Shutdown Valves

Standard types of valves intended for ESD service must achieve the highest degree of reliability and integrity.

The actuators are usually fail-safe hydraulic or pneumatic type and affect the valve’s ability to perform its shut-off function.

The main requirement of this kind of valve is that it can be relied on closure when called to do so under any kind of conditions and operation.

To grant the above, a new generation of special “Partial Stroke” devices are applied on the actuator in order to test the valve operation at specified periods.

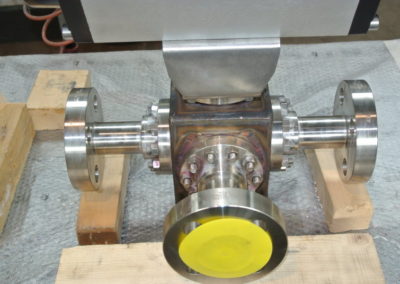

Double Block and Bleed Valves

Thanks to two obturators inserted in a single body, Double Block and Bleed valves assure double isolation and they provide the bleed function by means of a bleed or vent system located between the two obturators (ball, gate or needle). Different configurations are available: floating or trunnion mounted, full or reduced bore, with main advantages as:

- saving in dimensions, weight and costs;

- reduced leakage points

- reduced installation and maintenance requirements and cost

- compact design

- reduced stresses from loading and vibration

Request a quote

Contact Us

CONTROLFLUID s.r.l.

Via Braia, 55

16019 Ronco Scrivia (GE)

ITALIA (IT)

Tel. +39 010 9642630

Fax +39 010 9642641

Sede principale

Assemblaggio valvole motorizzate, elettriche e pneumatiche, ispezione finale e collaudi NDT

CONTROLFLUID s.r.l.

Stabilimenti di produzione di valvole a sfera

Via per Gallarate, 50

21010 Besnate (VA)

ITALIA (IT)

CONTROLFLUID s.r.l.

Stabilimento di produzione di Gate, Globe

and Check Valves

Via A. Mauri

20900 Monza (MB)

ITALIA (IT)

CONTROLFLUID - KOREA

Produzione estera

269, Hawmok-Dong

Gimhae-City Gyeongnam

KOREA (KR)