Company

Company

CONTROLFLUID has been established after split off from one of the most worldwide renowned Italian manufacturers of valves and components for the interception of fluids.

Ever since Controlfluid has succeeded in preserving its small, but very effective dimension, which is the key of its leading role among the companies operating in the same business and of the successful achievements in the most advanced technological challenges.

Controlfluid distinctive feature is its open minded cooperation with Customers, Engineers and End Users in order to facilitate their difficult and complex tasks.

Controlfluid long term experience, absolute flexibility and adaptability in meeting a wide range of requirements, together with its qualified operating skills, have made it a familiar name with many Companies operating in the Chemical, Petrochemical, Energy, Pharmaceutical, Food Processing and Shipbuilding Industries.

The very high quality and safety levels has been reached by Controlfluid production standards, from the resistance to high temperatures and pressures valves, to low temperatures and aggressiveness of more and more critical fluids.

Controlfluid Company Profile is available upon request.

Non-Destructive Examination

All the following NDT and inspections are available and performed in-house, utilizing our own instruments under the supervision of a Level II and Level III Inspectors:

Visual Examinations acc. to MSS-SP-55 by Steel Casting and Trade Association 3D Comparators

Dye Penetrant Examination acc. to ASME B16.34 and ASME V and VIII

Magnetic Particle Examination acc. to ASME B16.34 and ASME V and VIII (by Magnaflux Y6)

X-Ray acc. to ASME B16.34 and ASME V and VIII

Ultrasonic Examination acc. to ASME B16.34 and ASME V and VIII (by USMGO KRAUTKRAMER)

Positive Material Identification (by NITON XL2 980 G Goldd)

Chemical Composition & Mechanical Properties

Testing

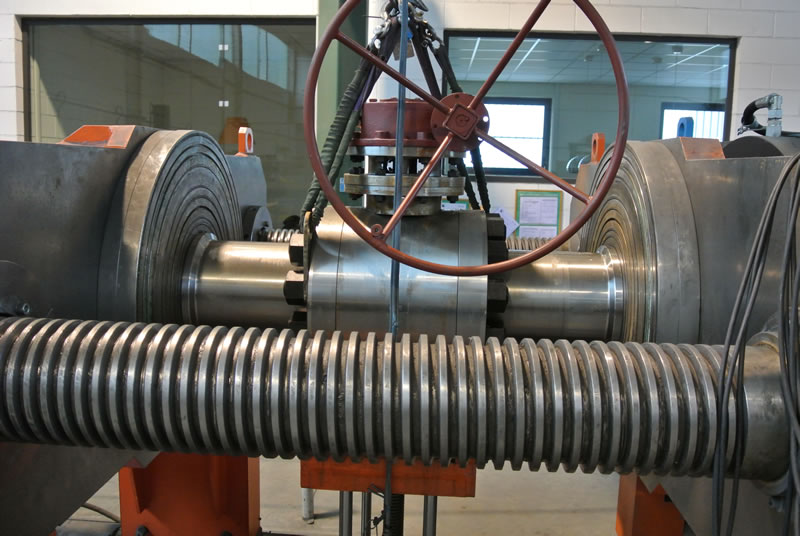

Before being dispatched, we perform on each valve hydraulic and pneumatic tests, according to the applicable standard (B16.34, API 598, API 6D) or to the Customer requirements when requested.

Valves having destination the EU market will be tagged in accordance to PED.

Testing Devices at factory

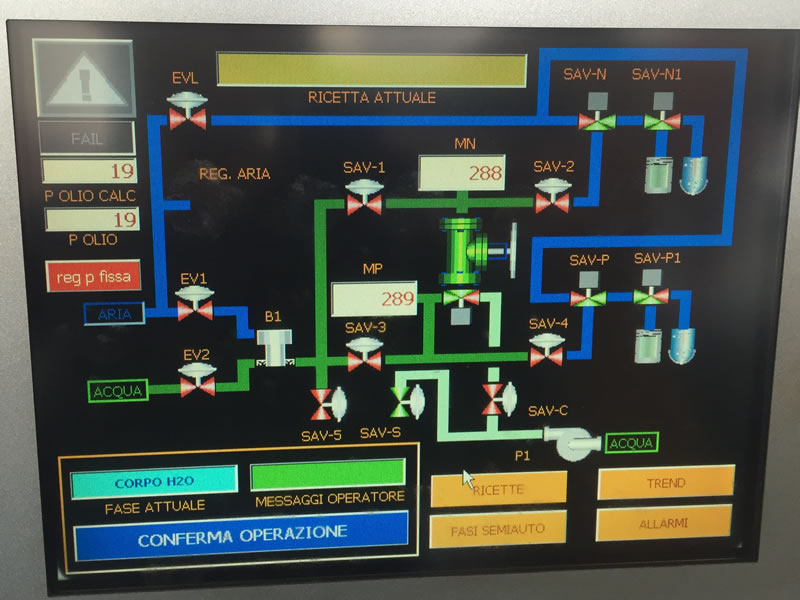

1 – Automatic Test Bench – Italcontrol – up to 12” valve size – class 4.500#

2 – Automatic Test Bench – Italcontrol – up to 48” valve size – class 2.500#

1 – Three Head Test Bench – Italcontrol – up to 6” valve size – class 2.500#

Request a quote

Contact Us

CONTROLFLUID s.r.l.

Via Braia, 55

16019 Ronco Scrivia (GE)

ITALIA (IT)

Tel. +39 010 9642630

Fax +39 010 9642641

Sede principale

Assemblaggio valvole motorizzate, elettriche e pneumatiche, ispezione finale e collaudi NDT

CONTROLFLUID s.r.l.

Stabilimenti di produzione di valvole a sfera

Via per Gallarate, 50

21010 Besnate (VA)

ITALIA (IT)

CONTROLFLUID s.r.l.

Stabilimento di produzione di Gate, Globe

and Check Valves

Via A. Mauri

20900 Monza (MB)

ITALIA (IT)

CONTROLFLUID - KOREA

Produzione estera

269, Hawmok-Dong

Gimhae-City Gyeongnam

KOREA (KR)